Economic & durable & eco

In recent years, cotton fabrics have been in a bad light due to their so-called excessive water consumption for cultivation. If we change our buying habits and don't buy our clothes worn out but wear Raw (unwashed), our consumption will drop drastically and people will no longer be forced to grow cotton in places where irrigation has to be done.

In this blog you will find even more details on why denim can be called a sustainable fabric.

I would like to demonstrate that denim, the fabric from which blue jeans are made, is an ecologically sustainable fabric. Everything that follows is the result of what the jeans pioneers put together almost 150 years ago in search of economic solutions. At the time an economic solution could also be ecological.

Legend has it that the Americans got their fabric from Nîmes in France, a fabric called "Serge de Nîmes". This fabric weave had the advantage of being very strong and heavy, but also the property that you can make a colored fabric by only dyeing half of the yarns used. The warp threads (the lengthwise direction of the fabric) are dyed, the weft threads (threads in the width of the fabric) remain undyed ecru.

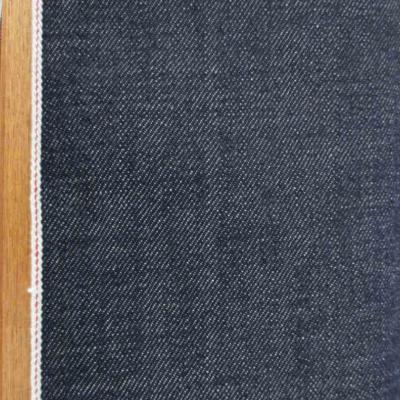

So after weaving you get a right side on the fabric that is colored and a reverse side that is almost ecru.

This Serge de Nimes, twill weave, is a warp face twill 3x1 where the warp threads, the blue ones, predominate on the right side of the fabric. In the picture you see that each blue thread goes repetitively over 3 ecru weft threads and then goes under 1 ecru weft thread .... Result on the right side you see 3 times more blue than on the purl side where you see 3 times more ecru.

- Advantage half of the cotton does not have to be dyed.eco

The blue warp threads are dyed before weaving, according to the method of rope dyeing, which means that the threads are immersed 8 times in an indigo dye bath, so only the outside is dyed than the threads.

- A saving of dyes again,eco

and with wear, the ecru interior appears, which results in the specific wear aspect of blue jeans. In this photo you can see the blue warp threads in cross section and you can clearly see the ecru core of the threads.

As mentioned, the threads in ropes are successively dipped in an indigo dye bath after which they are given time to oxidize and then go back to the next bath, usually 8 baths. These are large installations, but they usually have the advantage that only blue is painted and that there are no color changes where everything has to be rinsed and cleaned, in contrast to fast fashion where colors and designs have to be switched in small quantities. It goes without saying that this cleaning and rinsing results in a lot of energy, products and water wastage.

Godfrieds only uses Selfedge denim woven according to the original method of weaving with shuttle looms.

This has the advantage that the edge of the fabric called the selvedge (Selvage) is bound and does not fray.

In the photo on the left of the fabric. This selvedge, woven by the weaving mills in a color other than blue, red and / or ecru, is used in our garments and can be seen especially in the side seams of our jeans.

These seams therefore do not require additional treatments against fraying and ensure that the fabric is used all the way to the edge.

About 60 meters less stitching thread (per pants) needed to not finish the side seams, and a fabric gain of +/- 0.1 m² of fabric (per pants) along the fabric edges that would otherwise be thrown away.

- By using Selfedge we save resources.eco

We supply our trousers Raw unwashed, so they are not industrially mechanically or chemically or with lasers worn out.

So the customers have to wear out their jeans themselves, then you get cotton that has served and been used, not a disposable item.

- By wearing Raw no unnecessary machines, energy and raw materials have been lost.eco

The less the customer washes his pants, the better the wear, in the photo a new raw jeans with 365 days worn jeans that were washed 4 times.

Conclusion, raw Godfrieds jeans are a sustainable product.eco

Without mentioning that they are stitched in Belgium and consist of 100% vegetable raw materials, whether or not made to measure for an acceptable price.

Note: To make the story readable, statements or figures have been stated that may differ by applying different ways of working or constructions.